Manufacturers Sugar: Unlocking Quality, Sustainability, and Reliability in the Sugar Industry

In the global marketplace, the demand for high-quality sugar continues to rise exponentially, driven by increasing consumer preferences for natural ingredients, health consciousness, and sustainable production practices. At the heart of this thriving industry are the manufacturers sugar companies—powerhouses that meticulously produce and supply sugar destined for a multitude of industries including food & beverage, pharmaceuticals, and industrial applications. Leveraging the expertise of top-tier Brazil Sugar Top Suppliers, businesses worldwide can access premium sugar that meets the highest standards of quality, purity, and sustainability.

Understanding the Role of Manufacturers Sugar in the Global Supply Chain

Manufacturers sugar are specialized industry players responsible for transforming raw sugarcane and beet raw materials into refined, consumable products. These manufacturers not only produce bulk quantities but also focus on quality control, processing innovations, and sustainable practices that align with global standards. Their role is vital, ensuring that the final product delivered to end-users maintains consistency, safety, and excellent flavor profiles.

History and Evolution of Sugar Manufacturing

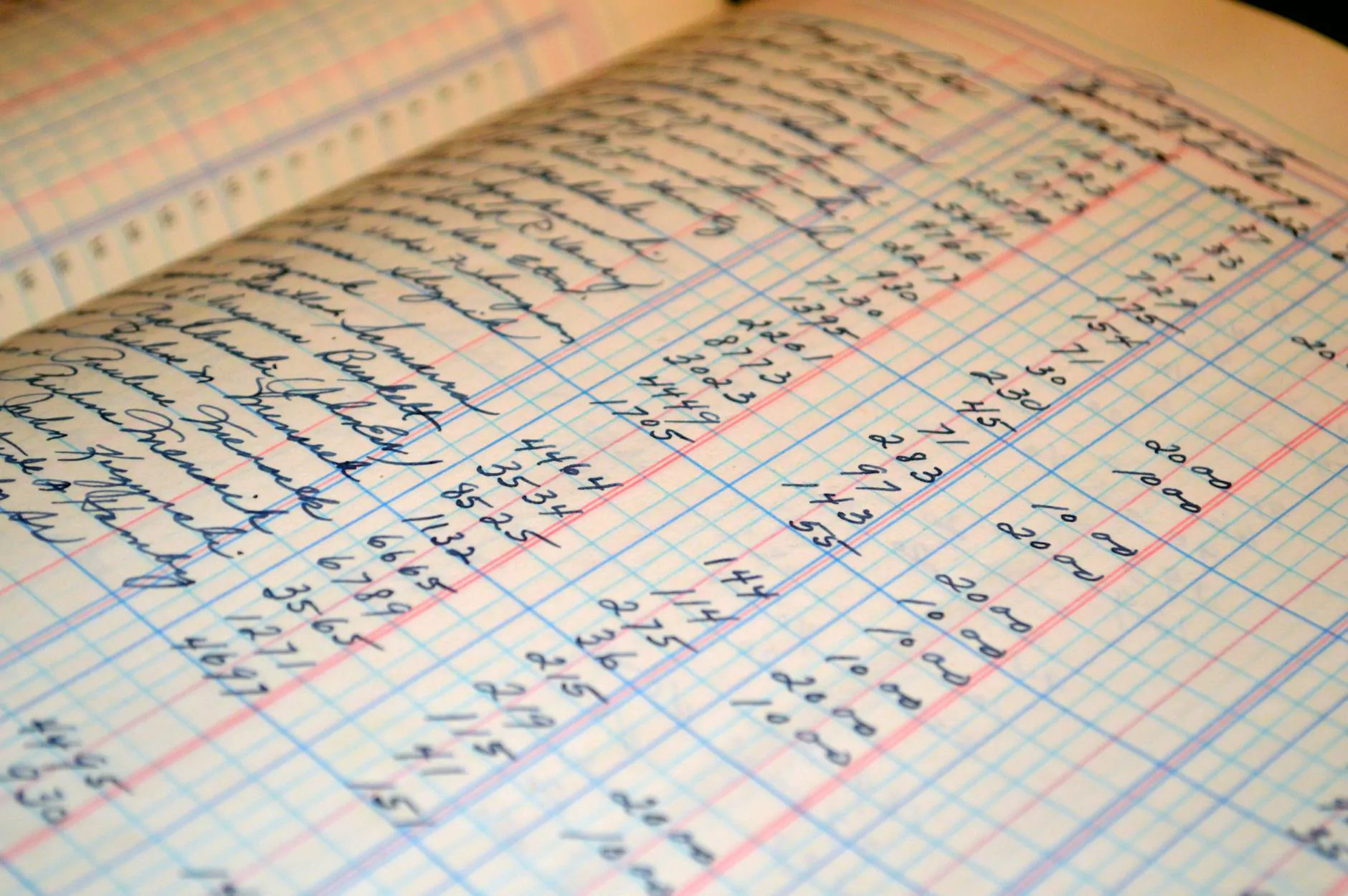

The history of sugar manufacturing dates back centuries, evolving from primitive extraction techniques to highly advanced industrial processes. Historically, sugar was a luxury item, but technological innovations, global trade, and agricultural development transformed it into an accessible commodity. Modern manufacturers sugar utilize state-of-the-art technology like centrifugation, crystallization, carbonation, and filtration to refine sugar to impeccable standards. The continuous evolution signifies the industry's commitment to efficiency, quality, and environmental responsibility.

Types of Manufacturers Sugar and Their Applications

Refined White Sugar

This is the most common form of sugar, characterized by its high purity and bright white appearance. It is widely used in baking, beverages, confectionery, and cooking. Top manufacturers strive to produce white sugar with minimal impurities, ensuring consistent quality across batches.

Raw Sugar

Raw sugar retains some natural molasses content, offering a richer flavor profile suitable for industrial applications and artisanal products. Manufacturers often supply raw sugar to markets seeking a more natural or less processed product.

Brown Sugar

Brown sugar contains residual molasses, lending it a moist texture and distinctive flavor. It is favored in baking and gourmet food production. Reliable sugar manufacturers emphasize purity and consistent moisture content for optimal culinary results.

Specialty Sugars

Including powdered sugar, liquid sugars, and specialty blends tailored to specific industrial needs or consumer preferences. Producers ensure these products meet stringent specifications for particle size, moisture, and purity.

Why Choose Brazil Sugar Top Suppliers for Your Sugar Needs?

Brazil is renowned globally for its extensive and high-quality sugarcane plantations, making it a prime source for manufacturers sugar. Leading companies like Brazil Sugar Top Suppliers epitomize excellence in sugar production, offering numerous advantages:

- Unmatched Quality: Leveraging advanced processing methods and strict quality standards to deliver superior sugar products.

- Sustainable Practices: Committing to environmental conservation, using renewable energy sources, and supporting eco-friendly harvesting methods.

- Consistent Supply: Reliable logistics and large-scale production capabilities ensure continuous availability for global clients.

- Competitive Pricing: Economies of scale translate into cost-effective purchasing options for bulk buyers.

- Custom Solutions: Ability to cater to specific industrial or consumer product requirements through tailored manufacturing processes.

The Manufacturing Process: From Cane to Crystal

The transformation of raw sugarcane or beets into refined sugar involves several intricate steps managed by sophisticated manufacturers sugar facilities:

- Harvesting: The journey begins with harvesting sugarcane or beets at peak ripeness, emphasizing sustainable farming practices to ensure soil health and crop productivity.

- Extraction: Crushing and milling extract juice from raw materials, minimizing waste and maximizing yield.

- Clarification: The juice undergoes clarification processes like carbonation or adding lime, removing impurities, and setting the stage for refining.

- Evaporation and Crystallization: Concentrating the juice through evaporation, then inducing crystallization under controlled conditions.

- Centrifugation: Separating sugar crystals from molasses, resulting in raw or refined sugar depending on further processing.

- Refinement: Additional refining steps—including filtration, bleaching, and drying—produce the final product suited for various applications.

- Packaging and Distribution: Ensuring products are packaged under strict hygiene standards for export and domestic markets.

Quality Assurance in Sugar Manufacturing

High-quality manufacturers sugar adhere rigorously to international standards such as ISO, HACCP, and BRC to assure safety, purity, and consistency. Critical quality control measures include:

- Laboratory Testing: Regular tests for moisture content, impurities, color, and purity levels.

- Traceability Systems: Tracking the origin and processing parameters of every batch for accountability.

- Certifications: Obtaining eco-certifications, fair trade labels, and organic certifications that appeal to conscious consumers and clients.

- Sustainability Reporting: Transparency in environmental impact, resource usage, and social responsibility initiatives.

Environmental and Social Responsibility in Sugar Manufacturing

Recognizing its environmental footprint, leading manufacturers sugar companies prioritize sustainability. Initiatives include:

- Reducing Water Consumption: Using advanced irrigation and recycling techniques to conserve water resources.

- Renewable Energy: Powering factories with solar, wind, and biomass energy sources.

- Waste Management: Recycling residual biomass and molasses into bioenergy or animal feed.

- Community Engagement: Supporting local communities through education, healthcare, and fair employment practices.

Future Trends in the Sugar Industry

The industry is poised for transformative growth, driven by innovations and changing consumer preferences:

- Health-Conscious Products: Development of low-calorie, sugar-reduced, or natural sweeteners derived from sugar manufacturing by-products.

- Biotechnological Advances: Use of biotechnological methods to improve crop yields and sugar extraction efficiency.

- Sustainable Certification Growth: Growing demand for products bearing sustainability certifications, influencing manufacturing standards.

- Digital Transformation: Implementing IoT, AI, and automation to optimize processes, quality control, and supply chain logistics.

Partnering with Brazil Sugar Top Suppliers: Your Gateway to Exceptional Manufacturers Sugar

Engaging with reputable suppliers like Brazil Sugar Top Suppliers ensures access to premium manufacturers sugar that comply with the highest standards of quality, sustainability, and reliability. Their extensive network and expertise facilitate seamless procurement, favorable pricing, and customized solutions tailored to your business needs. Whether you require bulk raw sugar, refined white sugar, or specialty formulations, choosing the right manufacturing partner can significantly impact your product quality and market success.

Conclusion: Embracing Excellence in Sugar Manufacturing for Business Growth

In conclusion, the significance of manufacturers sugar cannot be overstated in the global food and industrial sectors. The industry’s evolution towards sustainable, innovative, and high-quality production underscores its role in shaping a healthier, more environmentally conscious future. Partnering with leading suppliers like Brazil Sugar Top Suppliers offers invaluable advantages—ensuring that your business benefits from superior products, reliable supply chains, and a commitment to sustainability.

By understanding the intricacies of sugar manufacturing—from raw material sourcing to final product processing—and emphasizing quality assurance and environmental responsibility, your enterprise can thrive in a competitive market. The future holds promising innovations and growth opportunities, making it ideal to align yourself with the top manufacturers sugar players today.