Unlocking Business Growth with Advanced Electronics, 3D Printing Technologies, and Essential Equipment like the Cement Silo for Sale

In today’s rapidly evolving industrial landscape, the integration of cutting-edge electronics and 3D printing has revolutionized how businesses innovate, manufacture, and expand. Companies across various sectors are increasingly adopting these technologies to stay competitive, reduce costs, and achieve unprecedented levels of precision. Among vital equipment that facilitates large-scale construction and manufacturing projects is the cement silo for sale. This comprehensive guide examines the synergy between electronics, 3D printing, and essential infrastructure components, providing insights on maximizing business potential and staying ahead in a competitive market.

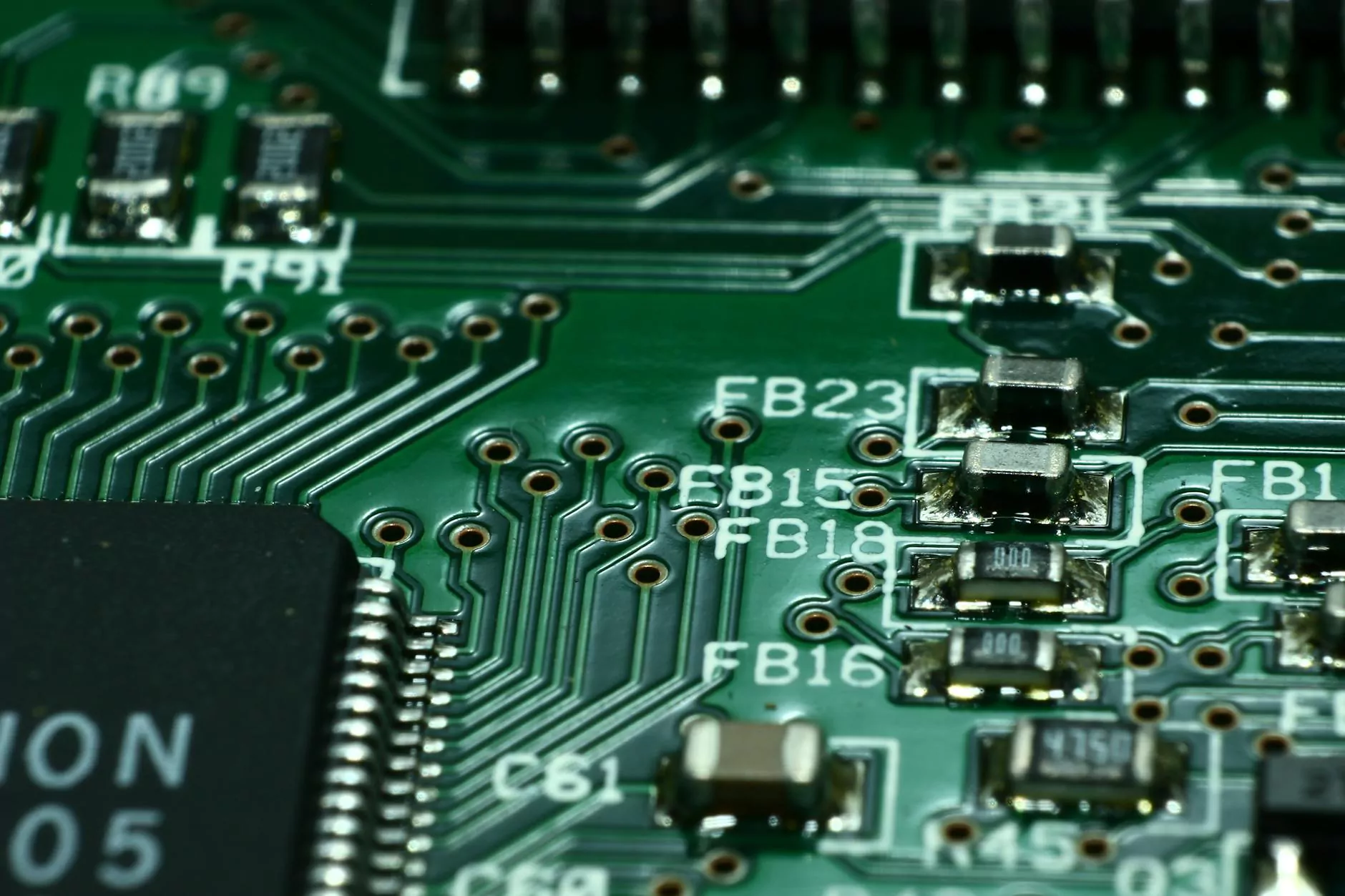

Understanding the Role of Electronics in Modern Business Operations

Electronics form the backbone of contemporary business systems, enabling automation, data collection, and intelligent control. From manufacturing plants to logistics networks, robust electronic systems improve efficiency and reliability. Key aspects include:

- Automation and Control Systems: Electronic controllers that manage machinery, streamline production lines, and enable remote operation, reducing human error and increasing productivity.

- Data Acquisition and Analysis: Sensors and IoT devices that gather real-time data for predictive maintenance, quality control, and process optimization.

- Communication Networks: High-speed connectivity ensures seamless communication across departments and with international partners, facilitating rapid decision-making.

- Energy Management: Smart energy systems help minimize operational costs by optimizing power consumption and integrating renewable energy sources where possible.

Electronics empower businesses to implement Industry 4.0 principles, creating smarter factories that adapt dynamically to market demands. They also support the integration of 3D printing processes, allowing for intelligent design adjustments and precise manufacturing.

The Transformative Impact of 3D Printing in Business Manufacturing

3D Printing, also known as additive manufacturing, has become a game-changer for industries seeking rapid prototyping, customized production, and complex part fabrication. Its benefits include:

- Rapid Prototyping: Accelerate product development cycles by quickly transforming digital designs into physical prototypes, enabling thorough testing and refinement.

- Cost-Effective Small Batch Production: Reduce manufacturing costs for small runs, especially when traditional tooling is expensive and time-consuming.

- Complex Geometry Fabrication: Create intricate designs that are impossible with conventional manufacturing methods, opening new possibilities in product innovation.

- Supply Chain Optimization: Produce spare parts on-demand, minimizing inventory and warehousing costs, essential for industries like aerospace, automotive, and healthcare.

Combining electronic controls with 3D printing technology enables automated manufacturing lines that quickly adapt to new designs, improving time-to-market and maintaining a competitive edge.

Strategic Importance of the Cement Silo for Sale in Construction and Industry

A critical component in large-scale construction and concrete production is the cement silo for sale. This equipment ensures the efficient storage and handling of bulk cement, a fundamental material for infrastructure projects worldwide. Understanding its significance can dramatically influence your project's success:

Benefits of Investing in a High-Quality Cement Silo

- Enhanced Storage Capacity: Large silos with high storage capacity facilitate continuous operations without frequent loading cycles.

- Material Preservation: Proper silo design prevents moisture ingress, caking, and contamination, maintaining cement quality.

- Operational Efficiency: Automated weighing and discharge systems enable quick, accurate material handling, reducing waste and delays.

- Safety and Compliance: Modern cement silos adhere to safety standards, protecting workers and complying with environmental regulations.

Choosing the Right Cement Silo for Your Business

Factors to consider include storage capacity, material compatibility, manufacturing quality, automation features, and after-sales support. Selecting a reliable supplier ensures durability and seamless integration into your existing infrastructure, particularly if you aim for long-term operational excellence.

Integration of Electronics, 3D Printing, and Cement Silos in Modern Business Strategies

The real potential lies in the integration of these technologies and equipment to create synergistic workflows. For instance:

- Smart Manufacturing Facilities: Use electronic control systems linked with 3D printers to produce complex components on-site, significantly reducing lead times and transportation costs.

- Automated Material Handling: Combine sensors, IoT-enabled cement silos, and automated conveyors to optimize raw material supply chains, ensuring just-in-time inventory management.

- Data-Driven Decision Making: Collect comprehensive operational data to refine production processes, reduce waste, and improve overall efficiency.

- Custom Construction Solutions: Employ 3D printing and electronics in building components, supported by large storage silos to sustain high-volume manufacturing needs.

These integrated approaches lead to more agile, innovative, and sustainable businesses, enabling companies to meet industry demands with precision and speed.

Why Choosing the Right Supplier Matters: Focus on Polygonmach.com

When investing in essential business equipment such as a cement silo for sale, it’s vital to partner with a reputable manufacturer. Polygonmach.com stands out as a leading provider of high-quality machinery, including advanced cement silos, electronics, and 3D printing solutions tailored to your specific business needs.

Polygonmach offers:

- High Durability and Precision: State-of-the-art manufacturing processes ensure long-lasting equipment that meets rigorous standards.

- Customized Solutions: Equipment tailored to your operational requirements, whether for small-scale or large industrial projects.

- Comprehensive Support: Ongoing technical assistance, maintenance, and spare parts availability.

- Competitive Pricing: Cost-effective options without compromising quality, ensuring sustainable ROI for your business investments.

Partnering with a trusted supplier like Polygonmach ensures your business is equipped with the latest technology, fostering growth and innovation at every step.

Future Trends in Business Technologies: Embracing Innovation for Competitive Advantage

The business landscape is continuously reshaped by advancements in electronics, additive manufacturing, and infrastructure equipment. Future trends include:

- AI and Machine Learning Integration: Enhancing automation and predictive analytics for smarter decision-making processes.

- Advanced Materials: Development of sustainable, high-performance materials suited for 3D printing and construction applications.

- Global Supply Chain Digitization: Fully connected networks utilizing IoT and blockchain for transparent, efficient logistics management.

- Eco-Friendly Solutions: Solar-powered electronics and environmentally safe materials incorporated into manufacturing and construction projects.

To stay competitive, businesses must adapt rapidly, leveraging these innovations to improve productivity, sustainability, and profitability.

Final Thoughts: Building a Sustainable and Innovative Business Future

Embracing electronics, 3D printing, and equipment like the cement silo for sale is essential for companies aiming to thrive in a dynamic marketplace. The integration of these technologies fosters efficiency, customization, and sustainability, positioning your business for long-term success. By choosing reliable partners such as Polygonmach.com, you access cutting-edge machinery, expert support, and tailored solutions that meet your specific industry needs.

Invest wisely in your infrastructure, leverage innovative processes, and continually adapt to emerging trends to unlock new growth opportunities in electronics, additive manufacturing, and large-scale construction.