Unlocking Precision: The Role of China CNC Lathe Machining Factories in Metal Fabrication

CNC (Computer Numerical Control) lathe machining has revolutionized the manufacturing landscape, particularly in countries like China, which are home to some of the most advanced and efficient CNC lathe machining factories in the world. These factories play an essential role in the broader scope of metal fabrication, supplying products and components that meet stringent quality standards while also catering to the diverse needs of industries ranging from automotive to aerospace.

What is CNC Lathe Machining?

CNC lathe machining is a subtractive manufacturing process where a rotating workpiece is shaped by cutting tools. It allows for high-speed, high-precision operations, making it ideal for producing complex shapes and parts at scale. CNC technology enables the automation of these machines, resulting in significant enhancements in productivity, repeatability, and quality control.

Why Choose a China CNC Lathe Machining Factory?

When considering a CNC lathe machining factory, especially one based in China, several factors position these operations ahead of their international counterparts:

- Cost Efficiency: China's vast resources and established supply chain allow for competitive pricing on CNC lathe machining services without compromising quality.

- Advanced Technology: Many Chinese CNC factories utilize state-of-the-art equipment and technology, ensuring precision engineering.

- Production Scalability: Chinese manufacturers can easily scale production to accommodate both small and large orders, making them highly versatile for various projects.

- Skilled Workforce: The workforce in China is highly trained in advanced machining techniques, contributing to superior craftsmanship and innovation.

Key Benefits of Partnering with a China CNC Lathe Machining Factory

Partnering with a China CNC lathe machining factory offers several distinct advantages:

1. High Precision and Quality

The use of computerized controls ensures that every piece produced is within tight tolerances, allowing manufacturers to produce intricate designs that meet specifications precisely. Quality assurance processes are stringent, reducing the likelihood of defects.

2. Rapid Prototyping

China CNC lathe machining factories excel in rapid prototyping, which allows businesses to bring their products to market faster. The agility in adjusting designs based on feedback becomes a competitive advantage.

3. Diverse Material Capability

From aluminum to titanium, CNC lathe machining in China can handle a variety of materials, offering customization for specific project requirements.

4. Cutting-Edge Innovation

Many Chinese factories are at the forefront of innovation, continually adopting new technologies like AI and IoT to optimize manufacturing processes and enhance productivity.

5. Strong Supply Chain Infrastructure

The well-established supply chain in China facilitates faster delivery times and better procurement strategies, which are critical for just-in-time manufacturing processes.

Deep Mould: Your Partner in Metal Fabrication

At Deep Mould, we pride ourselves on being a leader in the metal fabrication industry. Our alliance with leading China CNC lathe machining factories ensures that our clients benefit from high-quality, cost-effective machining solutions. Our commitment to excellence means that we leverage the benefits of CNC technology to help you achieve your project goals efficiently and effectively.

How Does CNC Machining Work?

The CNC machining process involves several critical steps:

- Design Creation: Using CAD software, engineers design the component specifications.

- CNC Programming: The design is translated into programmable language, which instructs the CNC machine on how to execute operations.

- Setup: Materials and tools are loaded into the CNC machine, ready for the machining process.

- Manufacturing: The CNC machine performs the machining operations automatically, creating the component per specifications.

- Quality Control: The finished product is inspected to ensure it meets quality standards before shipment.

Industries Benefiting from CNC Lathe Machining

Many industries significantly benefit from services provided by China CNC lathe machining factories:

- Aerospace: Precision parts are critical in aerospace applications, where safety and reliability are paramount.

- Automotive: Components manufactured for cars and trucks, ranging from engine parts to accessories.

- Medical Devices: Production of high-precision medical instruments and devices that require stringent compliance with safety regulations.

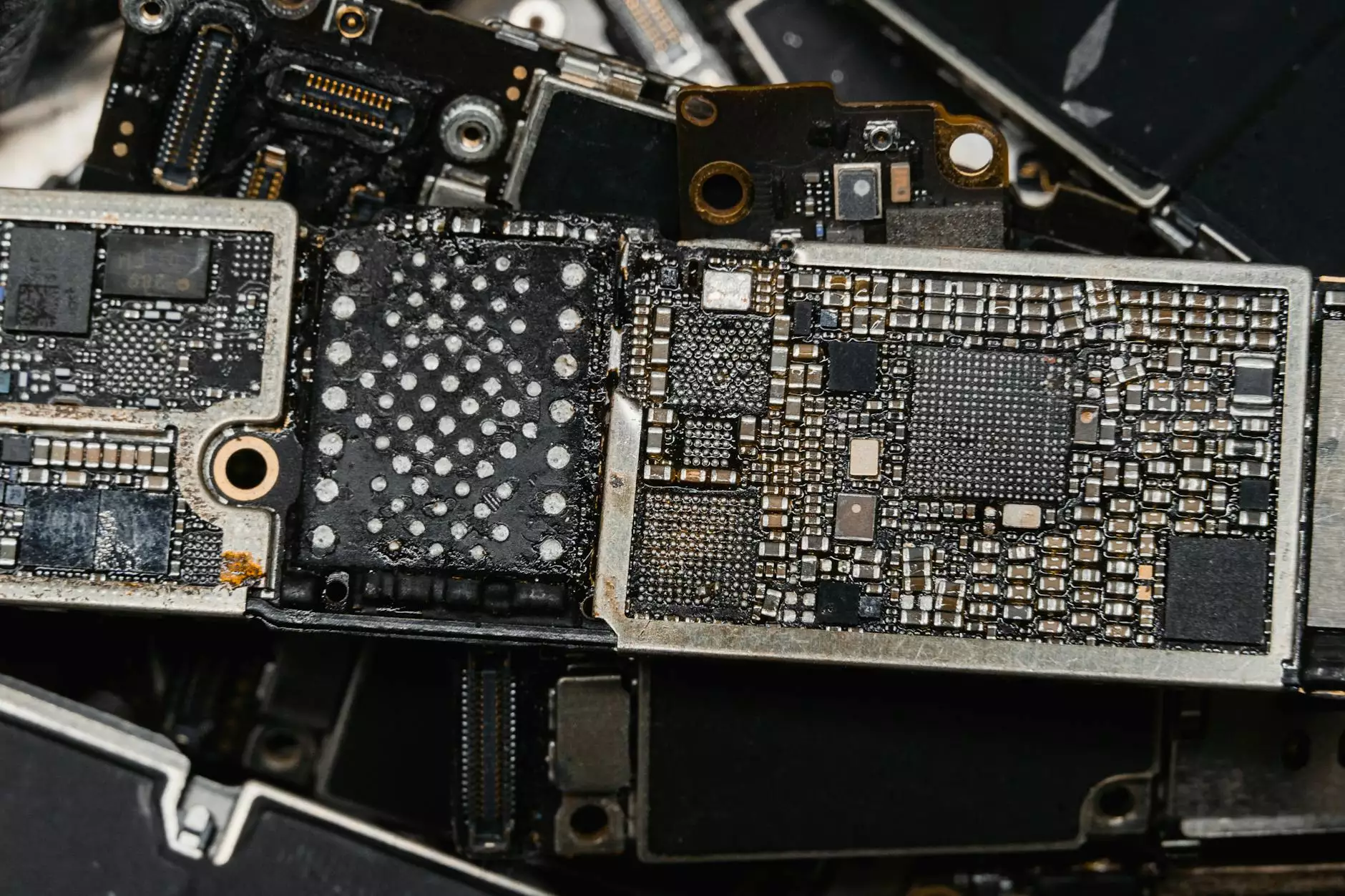

- Electronics: Manufacturing intricate components that form the backbone of modern electronics.

Choosing the Right CNC Machining Factory

When selecting a China CNC lathe machining factory, consider the following criteria:

1. Certification and Compliance

Ensure that the factory adheres to industry standards and holds relevant certifications, such as ISO 9001, to guarantee quality management practices.

2. Experience and Expertise

Look for a factory with extensive experience in your particular industry to ensure they understand the unique challenges and requirements.

3. Technology and Equipment

Review the machinery used and their CNC capabilities to ascertain whether they can meet your specific machining needs.

4. Customer Support and Communication

Effective communication can make or break a project. Look for a partner that prioritizes customer service and ensures that you are involved throughout the manufacturing process.

The Future of CNC Lathe Machining

The future of CNC lathe machining looks promising, with ongoing advancements in technology. Innovations such as smart manufacturing, automation, and advanced analytics are set to further improve the capabilities of CNC machining. Factories that embrace these trends will be better positioned to meet the evolving demands of the global market.

Conclusion

In conclusion, the realm of CNC lathe machining is pivotal to the evolution of manufacturing, particularly within the context of China’s dynamic industrial landscape. By partnering with reputable China CNC lathe machining factories like those associated with Deep Mould, businesses can leverage superior manufacturing capabilities, reduced costs, and heightened efficiency. As industries continue to grow and evolve, so too will the technological advancements in CNC machining, making it an indispensable part of modern manufacturing processes.

If you're considering an exciting venture into metal fabrication, look no further than Deep Mould. Our expertise combined with the precision of our partnered CNC lathe machining factories in China stands ready to bring your projects to life!